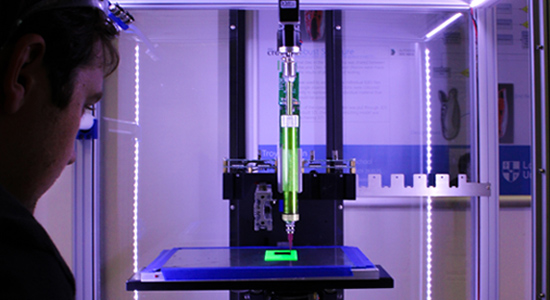

The rise of 3D printing has seen these devices becoming more accessible nowadays making things that were previously difficult to produce in a short space of time with decent accuracy now possible in a much quicker and often cheaper manner which is great for business and consumers alike, although a recent study by the HSE has found that emissions emitted by them could be potentially harmful, so we look at why and what you can do to stay safe – whether it be at home or work.

3D printing health risks

3D printing relies on a plastic filament which the printer heats up to melt it and then extrudes the plastic into the design required by the user layer by layer. Some filaments used in these printers has been found to release harmful to health chemicals, known as Styrene and Isocyanates when the heating process takes place.

Why is this dangerous?

Emissions from the 3D printing process emit the Volatile Organic Compounds (VOCs) which if breathed in it is believed could cause harm including pulmonary diseases, including cancer in some cases.

What should I do?

The HSE (Health and Safety Executive) have issued a report following research they conducted, and have provided some advice on reducing the risk which has been summarised below.

- Using a lower temperature for the printer nozzle to reduce emissions.

- Selecting an appropriate filament that doesn’t produce a high level of emissions.

- Enclose the printer with appropriate extraction and particulate filter to remove harmful VOC’s. Once the printing has finished a 20-minute period should elapse before the enclosure is opened.

3D Printing ultimately creates a potentially harmful fumes / vapours, and the Control of Substances Hazardous to Health Regulations (COSHH) 2002 requires employers to take action to control such substances. The Hierarchy of control states we should:

- Try to eliminate the hazard where possible

- Where we cannot do this, we substitute it (so a less hazardous material)

- If this cannot be done, we look at enclosing it with engineering controls / Extraction

- We must also train people and have a safe system of work.

- If there is still a residual risk then PPE can be considered as a last resort.

We can provide support at QUEST auditing your safety management system and giving suitable advice on recommended improvements. We can also give guidance on the risk assessment process and associated statutory duties under H&S legislation. We also offer a range of training courses which will give a deeper understanding of what is required to stay compliant. If you would like more information contact us today.